More Lives Saved - More Life Lived -Autoliv

Norma on Autolivi tütarettevõte mis toodab autode turvasüsteemi komponente ning kuulub Autolivi korporatsiooni, kelle lõppklientideks on pea kõik tuntud autovalmistajad üle maailma.

Üle 60 inseneri

Üle 150 tootekategooria

135 aastat kogemust

2 aktiivset tööpakkumist

Protsessid

Tootearendusosakonnas töötab 18 kogemustega arendusinsineri.

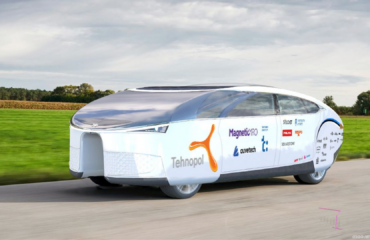

Arendusinseneride igapäevatööks on sõidu- ja veoauto ohutusrihmade, nende komponentide ja sõlmede väljatöötamine ning katsetuste korraldamine.

Töötamine Normas

Norma pakub igapäevast tööd ligikaudu kaheksasajale inimesele Tallinnast ja lähiümbrusest. Olles osa Autolivist on meil võimalus teha koostööd oma 70.000 kolleegiga!